Getting the Most from the Mower-Conditioner

by Kevin J. Shinners, Professor of Agricultural Engineering

Department of Biological Systems Engineering

University of Wisconsin-Madison

Introduction

A successful harvest of high quality forage starts with the proper use and set-up of the mower-conditioner. A key factor in achieving a high quality harvest is productivity – getting the crop cut and off the field as fast as possible to avoid weather damage. One way to achieve the needed productivity is to cut quickly. This is why the disk cutterbar mower-conditioner is rapidly becoming the dominant machine for cutting forage. Another way to achieve productivity is to help the crop dry to the desired moisture content as fast as possible. This can be achieved by proper level of conditioning and by forming a wide, uniform swath. Several new intensive conditioning systems have been introduced to the marketplace recently. These systems have generated substantial interest despite their considerable cost, which shows the frustrations forage producers have with slow drying rates. In this article, we’ll discuss the productivity advantages of disk cutterbar mower-conditioners, the drying rates produced by intensive conditioning systems, and how forage producers can help optimize the performance of their current mower-conditioners or windrowers.

Disk Cutterbar Mower-Conditioners

Engineers and machine operators know the formula for high field productivity – cut wide and cut fast. Of course there are limits to speed and width. Mower-conditioner width is limited by transport concerns, non-uniform cut in irregular fields and slow drying from the large mass of crop in the windrow or swath. The speed of cutting is limited by available power, field roughness and something engineers call “critical travel speed”. Critical travel speed is defined as the maximum ground speed at which the cutting systems can operate without pushing the crop forward and leaving a ragged, uneven cut. The cutting mechanism speed and the effective cutting length per stroke or revolution (“bite”) of the cutting mechanism dictates the critical travel speed. This speed is about 5 to 6 mph and 12 to 14 mph for sickle and disk cutterbar machines, respectively. These numbers tell an obvious story – disk cutterbar mower-conditioners are a lot more productive than sickle cutterbar machines. The adoption of disk machines will allow producers to harvest forage at a faster rate when weather conditions are ideal, resulting in higher overall forage quality.

Through much of the 1970’s and 1980’s, the sickle cutterbar mower-conditioner dominated the North American market. In Europe, where fine stem grasses are grown, disk cutterbar machines dominated. In the 1980’s, the disk cutterbar machines were introduced into the North American market. These machines experienced some initial resistance because some early models were known to have some very expensive failures of the cutter gear bed when large field obstructions were hit. However, the advantages of the disk cutterbar have slowly won over customers to the point where the industry is selling 2 disk cutterbar mower-conditioners for every 1 sickle cutterbar machine. Self-propelled windrowers are still dominated by sickle cutterbars, but over 25% of this market now use the disk cutterbar technology. When mower-conditioner and windrower sales are combined, fully 40% of the market is choosing the slower sickle cutterbar technology. So it would pay to look at the pros and cons of the technology so that producers can make an informed choice when purchasing a new machine.

Advantages of Disk Cutterbar

- Faster ground speed – more productive

- Better cutting in down, tangled crops

- Better cutting of fine stem grasses

- Will cut through gopher mounds, ant hills

- Replacing knives simpler and faster

- No reel needed – fewer moving parts

Advantages of Sickle Cutterbar

- Cost about 10 to 20% less per foot

- Requires about 50% less power per foot

- Open station tractor can be used

- Less streaking in light crops

- Lower repair costs if major obstruction hit

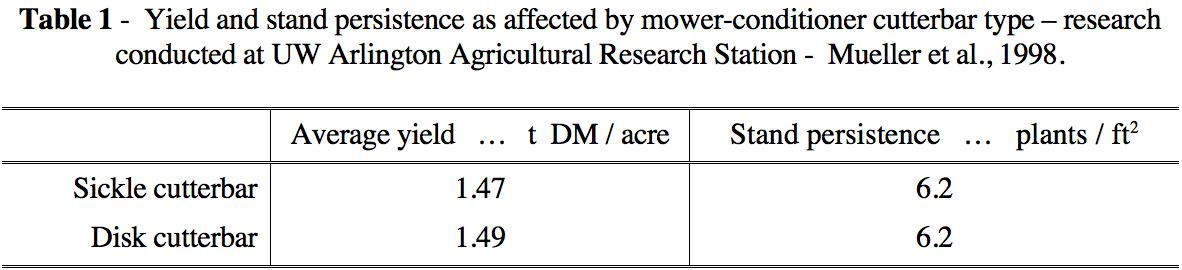

Manufacturers now offer disk cutterbars with segmented module gear beds and overload protection devices to reduce repair costs when damage occurs to the cutterbar. These new designs tend to isolate damage when an obstruction or rock is hit, greatly reducing the risk of large repair costs. Some alfalfa producers have expressed concern that the impact cutting of the disk cutterbar can cause damage to the plant crown that will lead to lower yield and stand persistence. Research on this subject showed that neither yield nor stand persistence was affected by the type of cutting system (Mueller et al., 1998).

This does not mean that mean that disk cutterbar mower-conditioners can’t damage both alfalfa and grass crops. Care must be taken to set the cutterbar cutting-angle so that scalping does not occur because, unlike a sickle cutterbar, the disk cutterbar will easily scalp without hesitation or plugging. The condition of the knives must also be checked regularly because the disk cutterbar will cut even if the knives are incredibly dull and worn. Dull and worn knives could produce a more ragged cut that might lead to plant health problems.

Conditioning Systems

Conventional Conditioning Systems

The forage plants we use today have survived through the centuries because they have been naturally selected to have drought tolerance. These mechanisms help hold onto the plant water during times of limited water availability. The waxy outer layer of the stem and the closing of the leaf stomata are two such drought resistance systems. Unfortunately, we’d like the plant to forget or lose these mechanisms as soon as the plant is cut from its root structure. We have to fight against these drought resistant mechanisms as we try to dry the crop. The conditioning system on the mower-conditioner is intended to crack, split or abrade the plant stem to provide easy routes for the plant water to escape, helping to overcome the natural tendency of the plant to hold onto water.

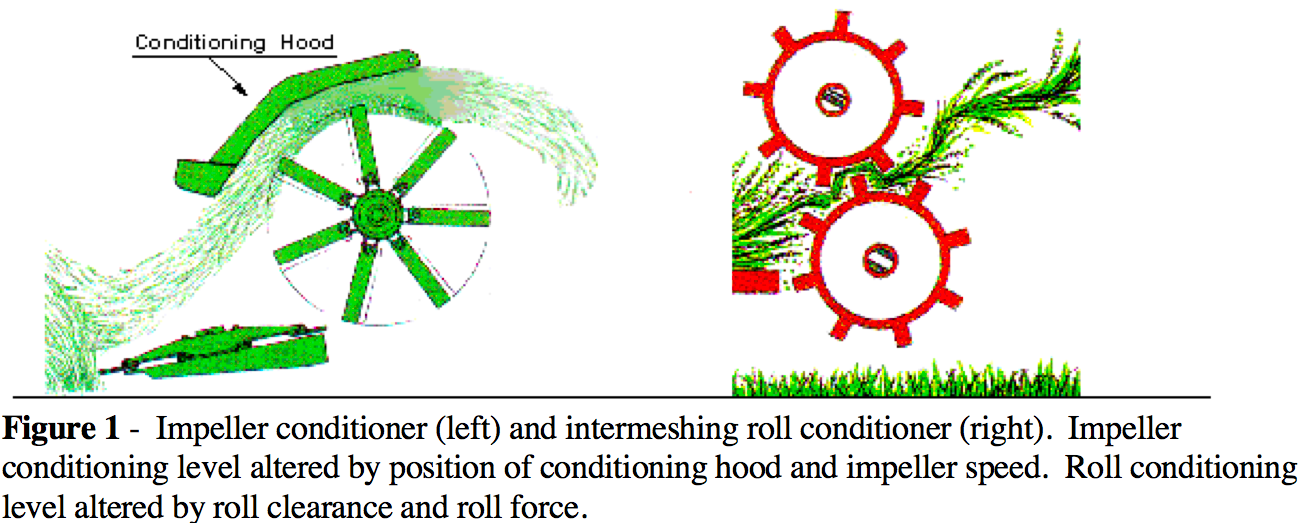

Three types of conditioning systems are typically available on mower-conditioners: intermeshing rubber or tire-core rolls, intermeshing steel rolls, and impellers. The impeller conditioner is offered only on machines with disk cutterbars. Intermeshing rolls have been used for decades because they offer a reasonable degree of conditioning with good feeding characteristics. Early rolls on pull-type conditioners used in the 1950’s used non-intermeshing rolls but they were prone to plugging, especially in wet, tangled 1st cutting alfalfa. The problems with feeding non-intermeshing rolls lead to the development of the intermeshing conditioning rolls we see in use today. Rolls condition the crop by creating cracks where the stem is bent by the intermeshing action of the rolls and also by crushing the stem at locations where the roll lugs squeeze the stem. The clearance between the rolls is critical. If roll clearance is too great, then stems can pass through virtually untouched. If roll clearance is too small, plant leaves can be clipped from the stem, roll wear can be excessive, and plugging can be more prevalent. We’ll discuss the importance of roll clearance in more detail later.

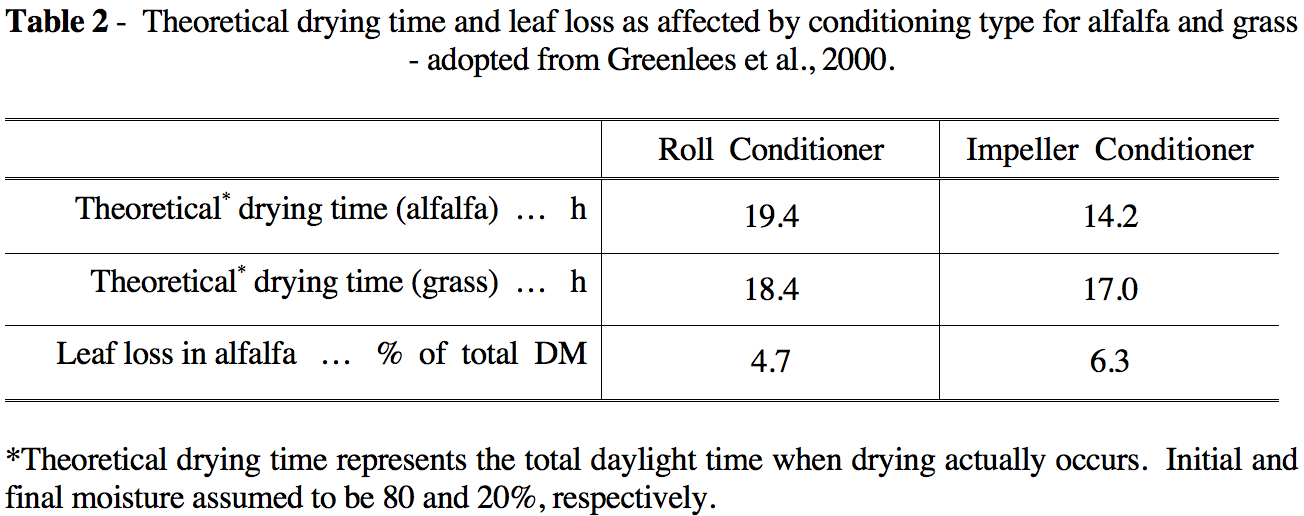

Impeller conditioners condition crop by impact of the fast moving hammers and by scuffing and abrading the stem as it passes along the conditioning hood. Impellers were originally developed to condition grasses, but now can be used to condition alfalfa or other leafy crops. Rotor speed is typically slowed about 30% to reduce the impact effect when conditioning alfalfa. Impellers are ideally suited for conditioning grasses. Grasses are difficult to condition with rolls because it is almost impossible to achieve a small enough roll clearance to crush the fine stems and leaves of most grasses. There is considerable debate as to the effectiveness of impeller conditioners with alfalfa. Some producers report faster drying rate while others are convinced otherwise. Side by side tests have shown impellers produced a faster drying rate with a higher leaf loss (Greenlees et al., 2000). The position of the conditioning hood is critical to the level of conditioning and producers need to make sure that this adjustment is properly made. There is speculation that some of the drying rate improvements that users of impellers have experienced may be due to the fact that roll clearance was not properly maintained on their previous machines.

Intensive Conditioning Systems

Within the last few years, there has been a new intensive conditioning system offered as a replacement for the conventional rolls on windrowers and mower-conditioners (Circle-C Equipment, Hermiston, OR 97838, 1-800-367-1847). This system has a set of non-intermeshing rubber rolls that operate at very small or virtually zero clearance. There is a crosshatch pattern machined into the face of the rolls to help improve feeding. The major advantage of these rolls is the opportunity to operate at very small or no clearance so that crushing can theoretically take place along the entire length of the stem.

Intermeshing rolls cannot operate at near zero clearance because the root and tip of the lugs have different diameters and therefore different speeds. This speed differential would create wear, noise and vibration if sufficient clearance were not maintained. The intensive conditioning system also uses an air bag roll loading systems that has the potential to produce higher roll force than conventional systems. The retail list price for this intensive roll conditioning system is about $15,000. A trail-behind pull-type machine with this roll system is also available at a retail list of between $19,500 and $24,500. The potential of the trail-behind pull-type system suffers from the requirement of a second pass through the field, decreasing productivity and increasing cost.

Producers from the Midwest have been anxious to know if this system actually provides sufficiently faster drying rate such that it’s substantial cost can be justified. Tests conducted by various researchers throughout the Midwest have found a roughly 10 to 15% increase in the drying rate compared to conventional conditioning. That translates to the crop achieving baling moisture 1½ to 2½ hours sooner than conventional practices. Whether this is a significant improvement depends on the situation. If baling could start at 1:00 PM instead of 4:00 PM, then it is more likely that baling can be completed on that day and there is less likelihood that the crop will have to sit through another night facing greater chance of rain damage. On the other hand, if baling commences at 11:00 AM instead of 1:00 PM, then in all likelihood both systems will allow baling to be finished that day and the intensive conditioning system would be more difficult to justify. Research has found that the faster drying rate of the intensive conditioner was realized right from the start of drying, so the system has potential to shorten the drying time for silage as well as dry hay.

Some of the advantage of the intensive conditioning system was reduced when the roll clearance of the conventional rolls was maintained at the lower range of recommended levels. The typical roll clearance recommendations are 0.060 (1/16) to 0.090 (3/32) inches. We have measured roll clearance on a number of producer machines around the Madison area and found an average roll clearance of about 1/8 inch, which is greater than the recommended values. Clearly, producers could improve the drying rate of the crop by simply maintaining the roll clearance at recommended levels, an improvement that would come at considerably lower cost than an intensive conditioning system. There are several reasons why typical roll clearance values are not set to specifications. Rolls wear with time and the loss of material at the roll surface will increase clearance. Roll adjustment, especially on older machines, is not easy to check or adjust, so producers are reluctant to maintain this adjustment. Some producers are reluctant to operate the rolls at the lower range of the recommended levels because of worry about excess leaf loss or increased risk of plugging the rolls. A simple method to measure the average roll clearance is given in the appendix to this article.

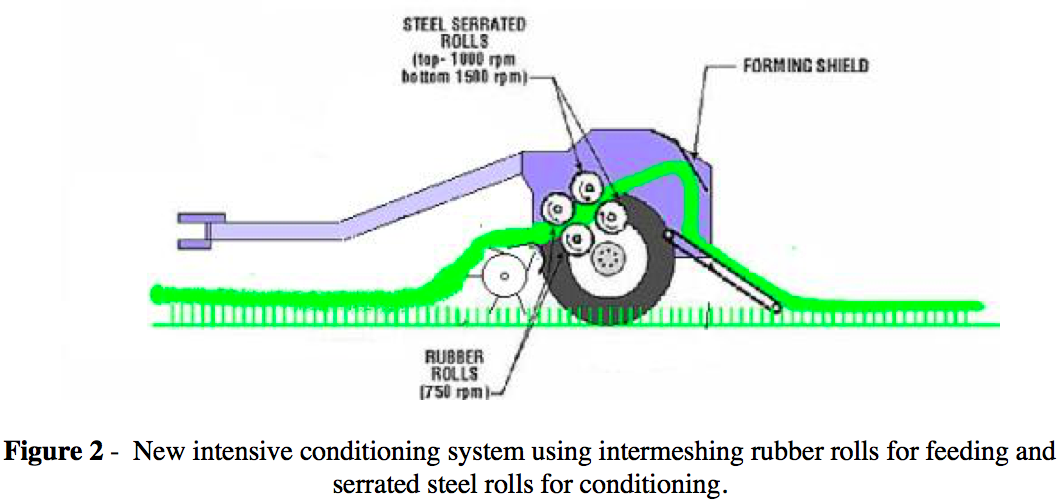

A new intensive conditioner has been introduced that claims that it conditions the stem by “macerating” (AgLand Equipment, Arborg, Manitoba, Canada, 1-888-933-4440). The figure below shows that this trail-behind pull-type machine has a set of intermeshing rubber rolls that feed a second set of serrated steel rolls. The serrated steel rolls operate at small clearance and differential speed. They are intended to nick and scratch the stem as a means of conditioning. This is a new machine that has not yet been used in Wisconsin. The retail list of the machine will be $14,500. Again, the potential of this system suffers from the requirement of a second pass through the field, decreasing productivity and increasing cost.

Other Factors That Affect Forage Drying Rate

Swath / Windrow Uniformity and Density

The most important factor we can control that affects the drying rate of the crop is the width of the swath and the swath density. For a given cut width, laying the crop in swath (about 70% of cut width) will reduce the drying time by about 25 to 40% compared to laying in a windrow (about 45% of cut width). This can be a reduction in drying rate of up to 6 h under typical Wisconsin weather during 2nd cutting. This is the easiest adjustment that can be made on the machine, typically just the flip of a lever, and the one that can pay the most dividends. The typical widths of most conditioning rolls are slightly less than 9 feet, so the widest swath that can be laid on most mower-conditioners and windrowers is about 8 feet. This means that as we move to wider machines to improve productivity, we are forced to increase the density of the subsequent swath. A very rough rule of thumb is that for every 11/2 foot of cut width beyond 9 feet, you’ll experience an increase in drying time to baling moisture of about 1 h. In other words, if you go from a 9 to a 12-foot mower-conditioner, the crop will take about 2 additional hours to bale because of the increase in swath density. Although it is very important to maximize the effect of incoming solar radiation by laying the crop wide, it is quite detrimental to lay the crop so wide that the tractor tires cannot be spread wide enough to prevent the swath from being driven over. If a typical tractor tire drives over the edge of an 8-foot wide swath, then fully 20% of the swath will dry at a much slower rate than the remaining 80%. And it’s the time when that slow drying 20% of the swath reaches baling moisture that will dictate when baling can begin.

Solar Insulation, Temperature, Soil Moisture, Relative Humidity and Wind

The most significant environmental factors that affect the drying rate of forages in order of importance are solar insolation (sunshine), temperature, soil moisture, relative humidity and wind velocity. We cannot control these factors, but we can try to maximize the positive effects of some of these factors. Laying the crop in a wide swath gives the most benefit from sunny conditions. Making a uniform, fluffy swath by having uniform feeding through the mower-conditioner will help promote good airflow through the crop. Finally, having the harvesting capability to cut as much crop as possible during good drying conditions will help maximize the quantity of high quality forage produced.

Conclusions

- Mower-conditioners and windrows that utilize disk cutterbar technology can help forage producers be more productive and produce more high quality forage. New disk cutterbar designs with segmented cutting modules and overload protection devices reduce the risk of costly repairs when rocks and obstructions are hit.

- Current roll conditioners can be quite effective at conditioning alfalfa, but roll clearance needs to be set and maintained at 0.060 (1/16) to 0.090 (3/32) inches to achieve effective conditioning. A simple technique for measuring average roll clearance is given in the appendix.

- Impeller conditioners may be an option for some producers, especially those who produce grass and alfalfa/grass mixtures. When using these conditioners in alfalfa, care must be taken to set impeller speed and hood position so that excess leaf loss does not occur.

- Intensive conditioning systems are generating much interest. At least one of these systems has shown some promise to improve forage drying rate, but the cost of the system may make payback difficult for some producers.

References

Mueller, D.H., D.J. Undersander and D.L. Frye. 1998. Disc and sickle mower-conditioners affect on stand persistence and yield. Proceeding of WI Forage Council 22nd Annual Forage Production and Use Symposium.

Greenlees, W.J., H.M. Hanna, K.J. Shinners, S.J. Marley, and T.B. Bailey. 2000. A comparison of four mower-conditioners on drying rate and leaf loss in alfalfa and grass. Applied Engineering in Agriculture. 16(1):15-21.