PDF Version

Key Facts

- Whenever possible, wait for drier soil conditions before entering fields.

- Reduce axles loads and lower equipment tire pressures.

- Keep axle widths similar when purchasing equipment.

- Manage equipment traffic patterns to minimize tire tracks.

- Rutting may not indicate that deep tillage or subsoiling is needed.

- Surface tillage alone may be sufficient to remove ruts and clay smearing.

- Cover crops can help.

Soil Compaction at Planting and Harvesting

Soil compaction is the increase in soil density due to pressure being applied to moist or wet soils, frequently from heavy vehicles. Compaction can happen any time of the year, but the risk at planting and harvest is often greater due to frequent rainfall during those months which makes soil more easily compacted. There are some simple guidelines you can use to minimize soil compaction, figure out where exactly it has occurred, and how to fix it.

Effects of Soil Compaction

Soil compaction reduces field productivity in many ways.

- Stunted roots: Plant roots are unable to push through compacted soils resulting in root systems unable to support healthy crops. Wisconsin research has shown compaction causing up to a 50% decrease in crop yields.

- Decreased internal drainage: Water (either rainfall or irrigation) will not internally drain through compacted soils resulting in longer time periods when the ground is too wet for field operations.

- Greater fertilizer needs: Prolonged wet conditions lead to soil nitrogen losses due to increased denitrification.

- Increased susceptibility to drought: Lower soil porosity leads to reduced water holding capacity.

- Increased fuel consumption: Tractors require more fuel to till compacted soils.

- Lower biological activity: Compacted soils contain fewer pore spaces– reducing soil aeration and biological functions, like residue decomposition.

- More soil erosion: When soils are compacted soil aggregates are destroyed and runoff and erosion are increased. Reduced internal drainage leads to greater runoff and lower soil moisture. Also, compacted soils have lower water holding capacity.

I Had to Plant/Harvest When My Fields Were Wet. Are They Compacted Now?

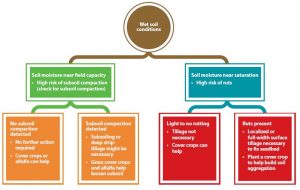

If you worked your fields while they were wet, there is a good chance your soils are compacted to some degree. However, the exact soil conditions when you worked your fields have a dramatic impact on the likelihood and type of soil compaction. Figure 1 is a flowchart you can use to help figure out if your soils are compacted and how they might be repaired. Most important in determining if compaction occurred is whether or not the field soil was saturated or at field-capacity.

Soil Water Content Effects on Compaction Potential

Soils are most susceptible to compaction when their water content is at or near field capacity because the proportion of soil pores filled with air and water is just right for compaction to occur. Soil well below its field capacity naturally contains tiny air pockets that work as shock absorbers that will allow them to support heavy weight without the soil particles smashing together. Also, soil aggregates help dissipate loads when the soil is drier.

Field capacity is defined as the soil water content after the soil has been saturated and allowed to drain freely for about 24-48 hours. This amount of water in the soil after this time period is just right to lubricate the movement of the soil particles and for the air to be forced out permanently.

It seems counterintuitive, but soils that are fully saturated (with their pores filled completely with water) are less susceptible to soil compaction than those at field moisture capacity. Since liquids are not compressible, a saturated soil can bear heavy equipment without compacting. However, soils at or near saturation are very prone to rutting and smearing near the surface.

Detecting Soil Compaction

There are several ways of figuring out if your soils are compacted. These including looking closely at the side of a small soil pit dug in your field, using a hand probe, or using a cone penetrometer. A detailed explanation of how to measure soil compaction can be found in UW-Extension Publication Soil compaction: causes, concerns, and cures (A3367). The penetrometer method will provide the most accurate results. UW Extension has a YouTube video showing how to use a cone penetrometer (see Additional Information). These instruments may be available for loan through your county Extension office.

The following are easily identified signs of soil compaction. It is probably worthwhile to conduct an in-depth investigation in the areas where these signs are seen.

On the soil surface

- Dense surface clods that don’t break down after rainfall or tillage

- Water ponding in tracks and headlands

- Wheel tracks with a smeared or glazed appearance

- Poor plant growth and stands

- Uneven plant growth or yields

- Plant leaf yellowing

Under the soil surface

- A hard zone of soil immediately below the depth of cultivation

- Hard clods that don’t break when squeezed by hand

- No structure to the soil

- Misshapen or shallow crop roots (‘J-rooting or pancake roots)

How to Prevent Compaction

Wait for drier conditions: The single most effective way to prevent compaction is to stay off wet fields for as long as possible. Soils are most susceptible to compaction 24-72 hours following a soaking rain, depending on soil type.

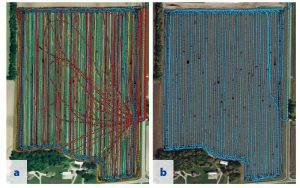

Manage farm traffic: Maintain repeated travel patterns between transport equipment and the harvester (i.e. driving in the same wheel track) can reduce the damage of operating on wet soils and will confine damage to specific and well-known locations in the field (see figure 2.) Global Positioning System (GPS) guidance is very helpful, but regular traffic patterns can also be achieved with some awareness and discipline on the part of the operator.

Optimize vehicle parameters:

- Maintain tires at the tire manufacturer’s recommended pressure to spread the machine’s weight over a greater surface area.

- Attach dual wheels wherever possible.

- Use machines equipped with tracks to spread the machine’s weight over a greater surface area. Using machines with uniform wheel track spacing reduces the risk of soil compaction (Figure 2).

- Consider carrying half or reduced loads out of the field.

- Use tractor-based transport equipment such as grain or dump within the field and load transport trucks (which have high pressure tires) at the edge of the field.

Figure 2.Part a shows an uncoordinated traffic pattern of two mergers, one forage harvester, and six transport trucks collected once per second during harvest. Part b shows the same field with a simulated traffic pattern where every machine follows in the path of the forage harvester. Although the entire field is impacted by machinery in both scenarios, corrective measures would be needed only on tire ruts from managed traffic (b) rather than the entire field (a).

How to Restore Compacted Surface Soils

Light Tillage: If ruts are present, surface tillage will be needed to improve the seedbed for planting operations. Tillage can be localized only to rutted areas. The presence of ruts does not mean you definitively have compacted soil below the surface.

Cover Crops: If shallow compaction (less than 6 inches deep) is detected, planting a cover crop will help to break apart the compacted soil and restore soil aggregation through natural root action. Fibrous- rooted crops (e.g. cereal rye) are more effective than tap-rooted cover crops (e.g.clover).

Freeze/Thaw: Winter freeze and thaw conditions may also help alleviate shallow compaction depending on soil type and other conditions. Compaction should be measured with a penetrometer in the fall and spring to determine effectiveness.

How to Restore Compacted Subsurface Soils

Deep Tillage: If subsoil compaction (deeper than 6″) is detected, sub-soiling or deep strip-tilling can be helpful. Deep tilling involves breaking up a hard pan using long shanks usually to a depth of 12-15”. This should only be done when the soil is at a moisture that allows the soil to crumble at the depth you are tilling. Till only to just below the compacted zone (2” to 3” below) as deeper tilling risks even deeper compaction and uses much more fuel. Deep tilling has shown yield benefits in sandy to clay loams but in finer textured soils the benefits may be short-term due to recompaction.

Vary Tillage Depths: If a subsurface hardpan of soil has developed, tillage depth may be altered to break this up. Tillage is not a permanent solution to address oil compaction. Identify practices that caused the compaction and modify as needed.

Restoration for No-till/ Low-till fields

If ruts must be repaired for seedbed planting, tillage in only the affected areas is recommended. lage fields have a greater ability to recover from compaction than that of conventional tillage managed soils. Soils in long-term no-till fields have a greater ability to recover from compaction than soils managed with conventional tillage. The higher organic matter content and aggregation normally found in no-till soils makes them more resistant to soil compaction and resilient in recovery. Research from Kentucky shows that surface compaction in a no-till field disappeared completely after two years of normal operations (Murdoch and James, 2008).

Additional information

A You Tube video “Using a penetrometer to detect soil compaction” can be accessed at: https://youtu.be/Zq_785JqRq8?list=PLF17555C62D9A378B

Authors

Francisco Arriaga, Assistant Professor, Department of Soil Science, UW Madison/Extension; farriaga@wisc.edu

Brian Luck, Assistant Professor, Biological Systems Engineering Department, UW Madison/Extension; bluck@wisc.edu

Geoffrey Siemering

References

Compaction, Tillage Method, and Subsoiling Effects on Crop Production (AGR-197). 2008 University of Kentucky Cooperative Extension Service. Lloyd W. Murdoch, John James

Soil compaction: Causes, concerns, and cures(A3367). 2008. University of Wisconsin Extension. https://learningstore.extension.wisc.edu/Soil-Comapction-Causes-Concerns-and Cures-P1419.aspx